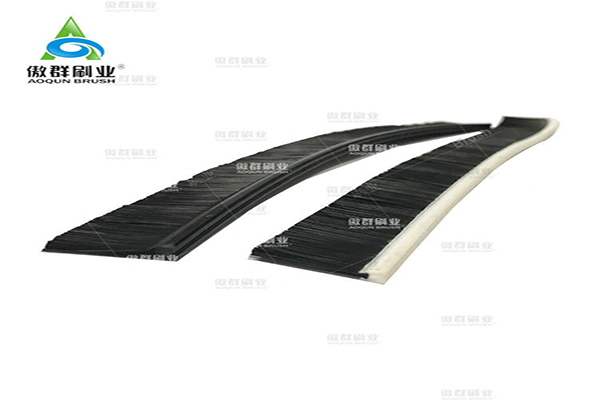

Like the structure of the Aluminum Alloy Strip Brush, the strip brush of the rubber strip base is also composed of three parts: a base, a fastening line and a brush wire.

The rubber strips of the base are generally made of PVC, TPV and TPE materials, which have the characteristics of strong adhesion, good resilience, anti-collision and shock-proof; while the wool is customized according to the actual use, and mostly uses PA, PP, PBT, PET Waiting for wool.

Compared with ordinary strip brushes, these strip brushes have better insulation, water resistance and temperature resistance, so they are mostly made into Screen Door Anti-Pinch Brushes, Sound Insulation Door Noise Reduction Brushes, Vacuum Cleaner Brush machines and Mechanical Seal Brushes. In addition, the adhesive strip has the characteristics of easy bending, the shape can be changed according to external force, and it is easy to perform processing procedures such as hot pressing, gluing, and bonding, which is very popular among industrial manufacturers.

Aoqun Brush Industry has been making brushes for nearly 20 years. It can be regarded as a veteran in the brush industry. The strip brushes produced by the rubber strip base can be customized into various special-shaped strip brushes according to the actual use of customers. If you need to know more For related information, please contact Aoqun customer service.

escanear a wechat

escanear a wechat